I was working in a company for the past ten years who has used "Lean" along with a little "Six Sigma" as the improvement strategy. Over the last year or two I noticed that the term “Operational Excellence" (OpEx for short) is currently being used to describe this overall idea of business improvement and transformation. OpEx seems to be the "soup-du-jour" for progressive Continuous Improvement focused organizations.

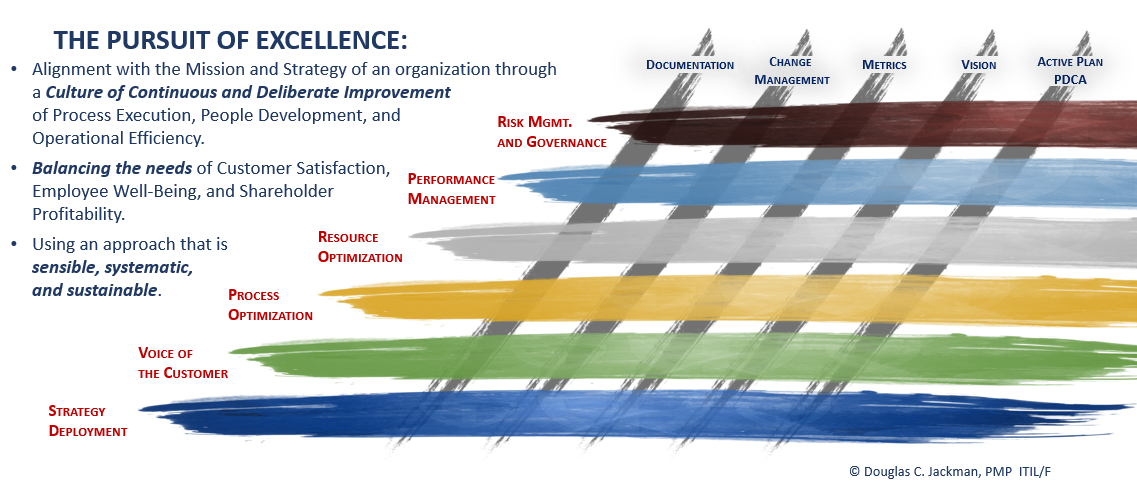

After a lot of reading and thinking, and boiling down a lot of fancy-sounding definitions, I think a simple and understandable definition of OpEx is:

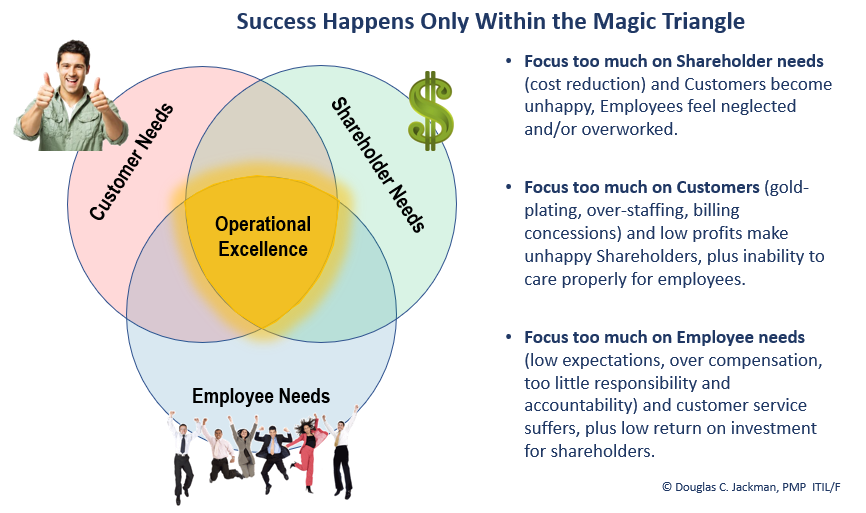

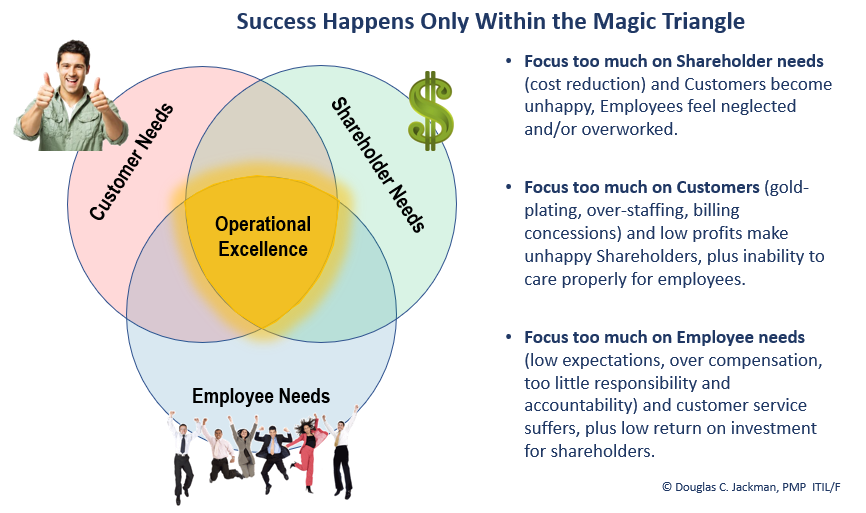

Unfortunately, in many cases, operational management focuses too heavily on cost cutting. This often takes the form of "Resource Optimization" in the form of layoffs or "right-sizing" and very little effort is put into "Process Optimization" or "Materials Optimization."

In most cases like this, while the Shareholders are pleased with the resulting increases to operating margin, the customer feels shortchanged and dismayed by a drop in timeliness and quality of delivery, and employees feel disrespected and fear for their future employment. This imbalance is not sustainable, and as such, companies that are short-sighted will find their success in the market dwindling over time.

Over the years it has become increasingly obvious that sound strategy must encompass more than just

increasing revenue and cutting costs. To be successful and sustainable the strategy must include efforts to

increase value to the customer and very importantly, must work to

empower employees, improve job satisfaction, and develop careers as well.

Cost savings CAN be achieved without forcing the burden onto the workforce. Here is a great article about how one company saves millions in cost without having to attack its own work force:

United Airlines - In-Flight Magazine production change saves nearly $300,000 per year

The easiest way to ensure employees are learning and practicing the concepts of Operational Excellence is for them to adopt and get into the habit of exhibiting the same best practices expected from a lean organization:

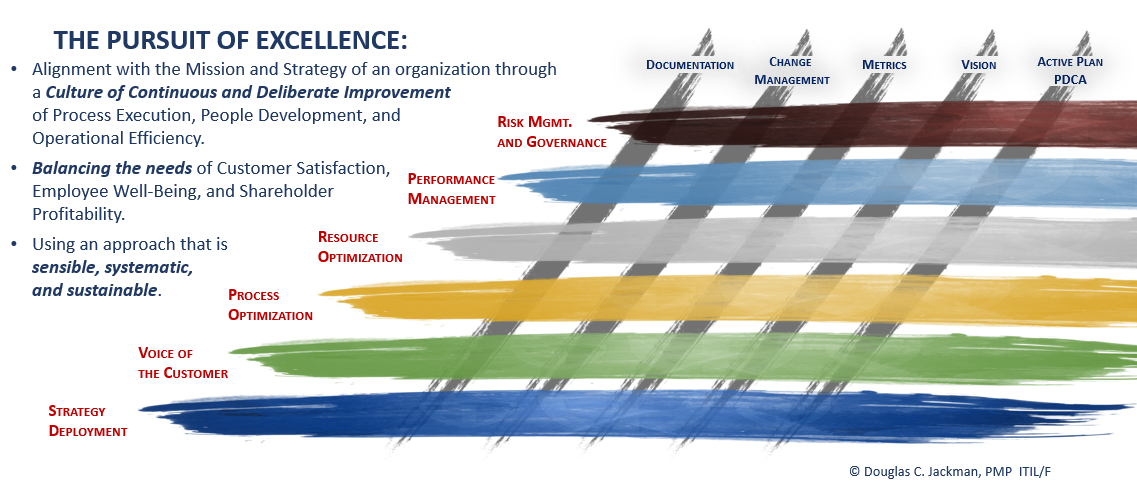

Conceptualized as a matrix with operational and improvement principles supporting each other throughout.

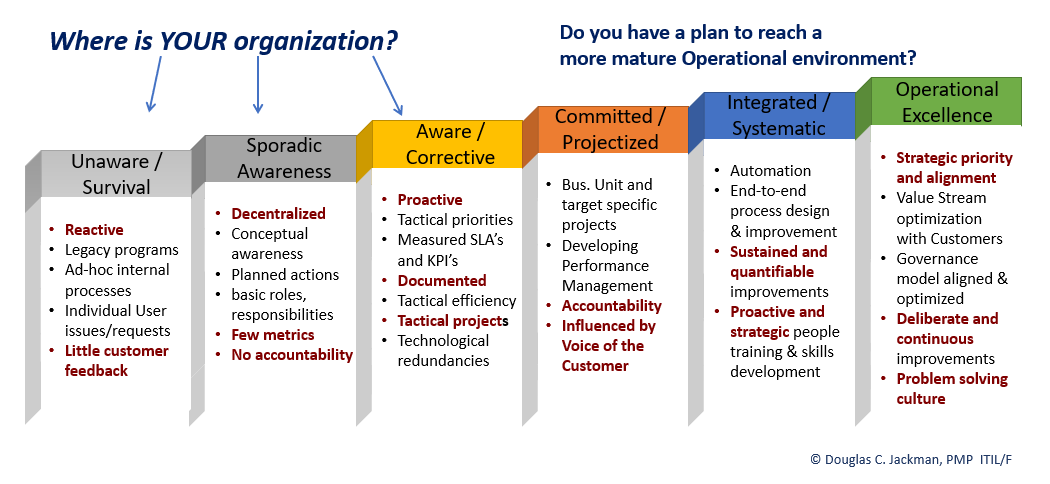

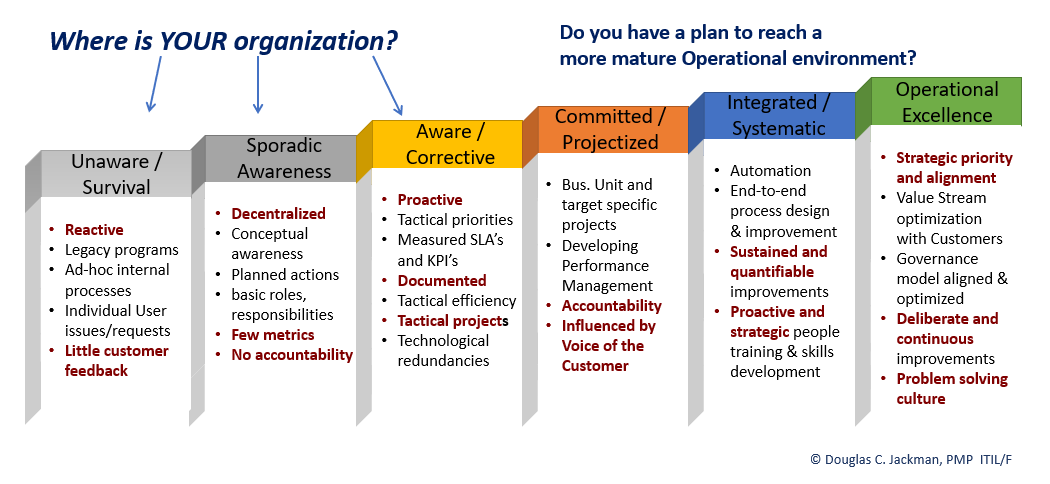

How mature is YOUR organization when it comes to Operational Excellence?